About

Maheshwari Industries which was started with a modest beginning as Parmeshwari Mechanic works. Initially engaged in production of Killen Valves, Burners and Nozzles used in Ceramic Industries. Thrust and craving for precision manufacturing motivated a group of two entrepreneurs towards making precise machined parts. With the vision of being favored supplier in this category, Maheshwari Industries was established way back in Year – 2006.

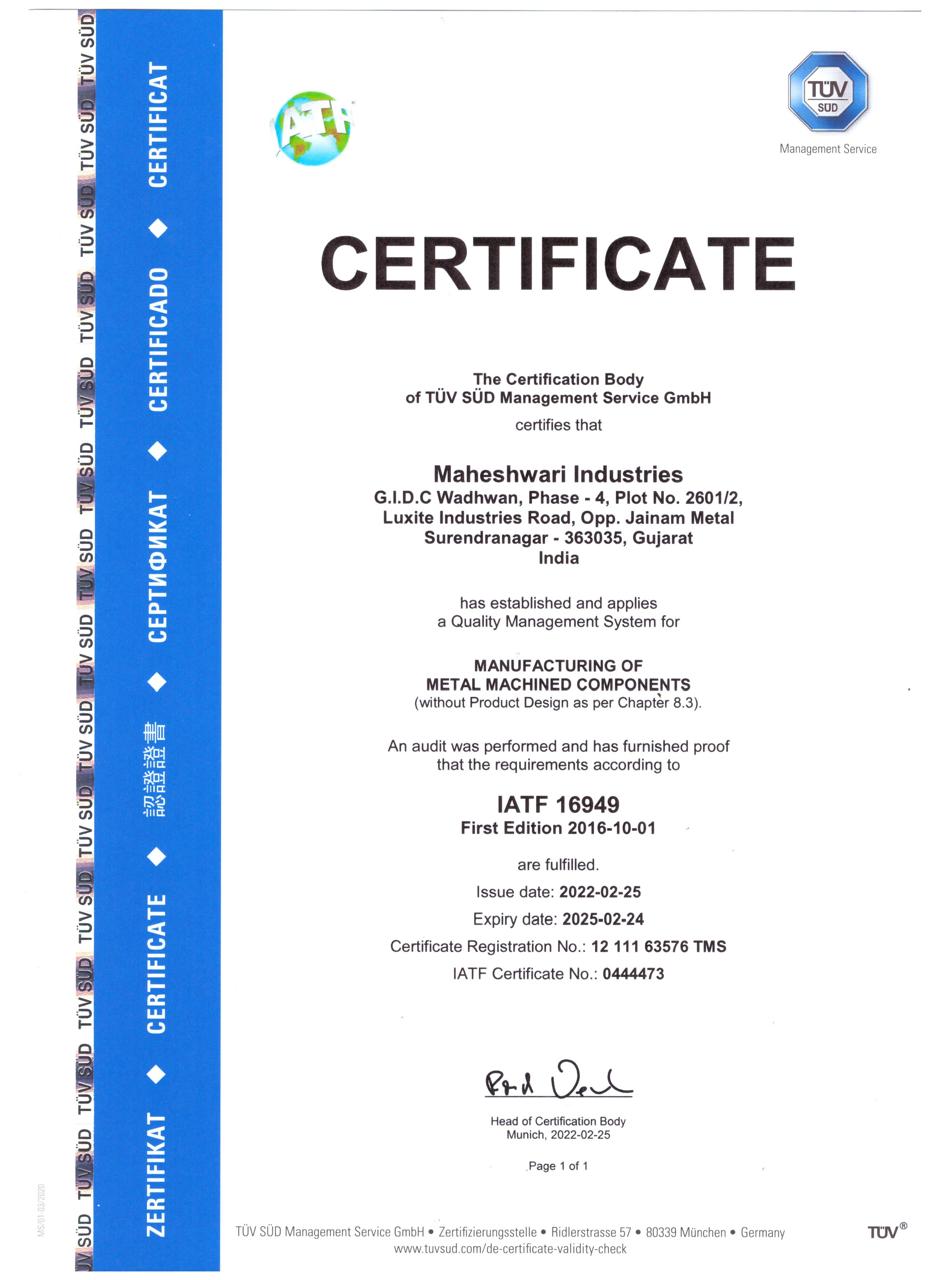

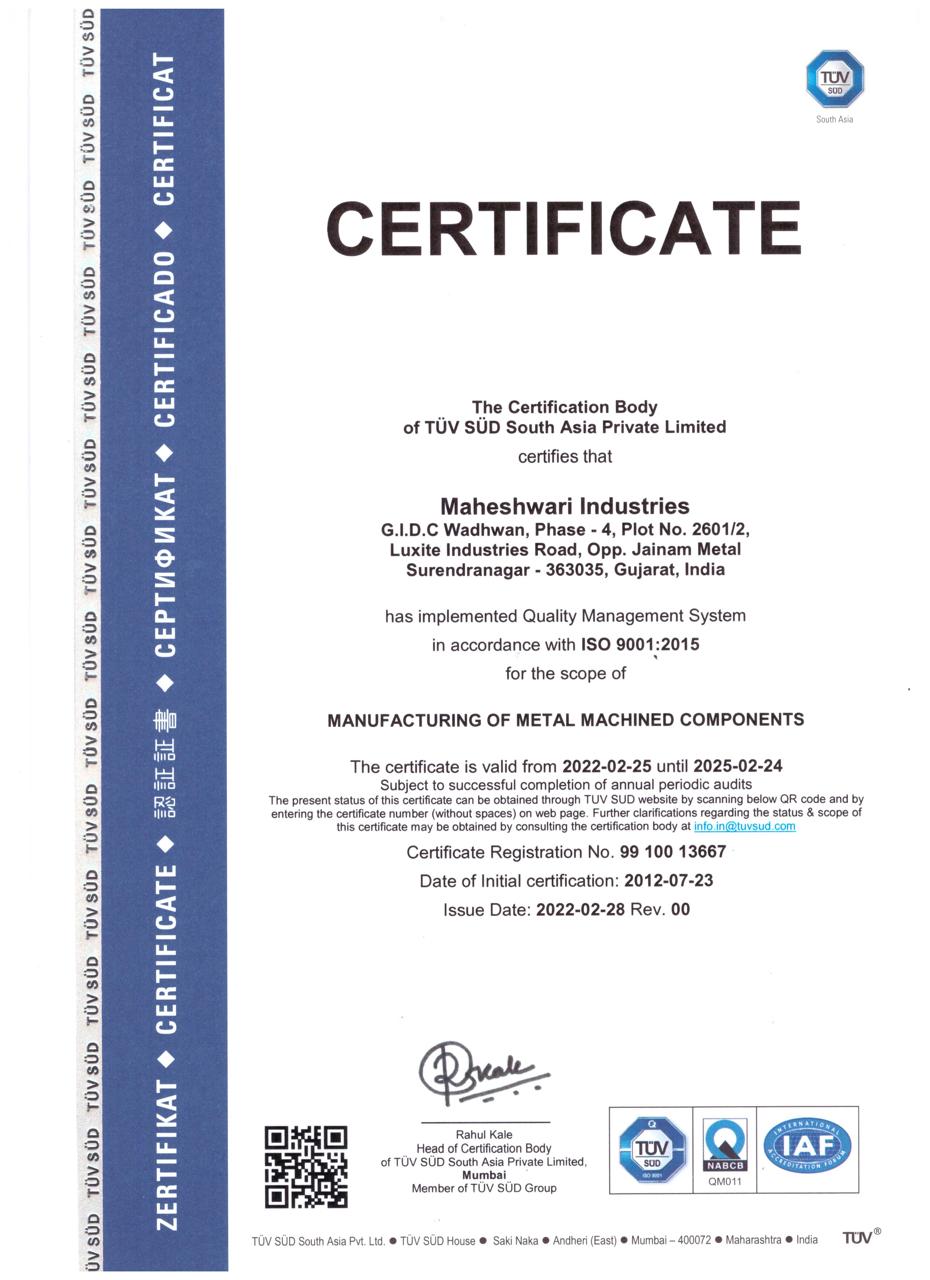

Currently, We offer a single stop solution for precise Turned and Machined components. With the aim of delighting our worldwide customers with engineering excellence, Zero defect policy, 100% delivery ratings, Innovation and continuous improvements. We are one of the best in industry setup of precision machines involving fleet of Japanese machines. We are an ISO – 9001 : 2015 and IATF – 16949 : 2016 certified company from TUV SUD (South Asia).

Our Team

We have a dedicated and visionary management

Mr. Dilip Rathod

Chairman

He is founder and born technocrat person having experience of 35 + years in manufacturing industries. He has invented many unique method of manufacturing. Now he is investing his time to build young team and make them competent by giving training frequently.

Mr. Jitendra Rathod

Managing Director

A Techno savvy entrepreneur with more than 25 years of expertise in the field of machining and management. Visionary leader and founder of the company along with guide and mentor. Mr. Rathod is a reputed name in the Surendranagar, Gujarat entrepreneur group. Simplicity and resilience paid off to this hard-working entrepreneur. Today he is guiding a team of more than 50 people and feeding as many more families with his company’s presence in Surendranagar. Mr. Rathod is a committed with values like integrity, honesty and adding value to others.

Mr. Mehul Rathod

Joint MD

Mehul Rathod is a graduate and very young dynamic leader. He is having an experience of more than 7 years of the industries in regard to precision machining. He manages and monitors the entire process cycle of the company.

Manufacturing areas

We have two manufacturing units at Surendranagar, Gujarat India adjoining to each other with occupied space spanning over 2500 Sq. Meters. Our state-of-the-art manufacturing facilities are a mix of traditional and modern manufacturing setups. Our new facility is equipped with a solar rooftop for green energy generation, Keeping in view of sustainable future. Also, we have acquired a land for our upcoming plant in the heart of modern industry in the city of Ahmedabad.

Machining Capibilities

Our best-in-class machining setup consists of CNC Turning / Machining centers – VMC / CNC Cylindrical Grinding machines / Dilling machines / Hydraulic presses / Lapping machines / Milling Machines / Conventional Lathe machines / Laser Marking machine and Industrial Robot. We have a fleet of more than 40 machines and are still investing in new ones. Our management is dynamic and ready to invest in case of right opportunity.

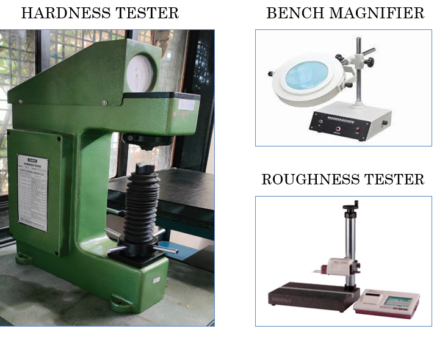

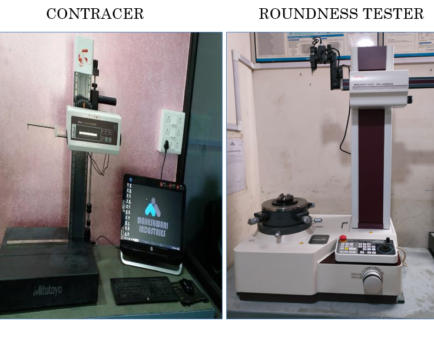

Quality Testing &

Measuring Facility

Maheshwari Industries believes in benchmarking, testing and measurement requirements in line with our customers’ expectations. Once parts are tested and certified it should be fit for purpose. Keeping this philosophy in our DNA we have invested in all modern measurement equipment and testing facilities.